The Steel Division has been meeting the expectations of customers in various countries by offering integrated services, including coil center operations, and providing a wide range of materials and services. In the midst of what is often referred to as a "once-in-a-century transformation" in manufacturing, how is the Steel Division adapting to changes in the materials it handles? We spoke with two members of the Steel Division to learn more.

*Note: The information is current as of March 2025.

Handling a Variety of Materials Close to Our Customers

- ーCould you provide an overview of the Steel Division's business?

- Hozawa: Guided by the "Three Reality principle"ーwhich emphasizes genba [actual place], genbutsu [actual thing] and genjitsu [actual situation]ーour company operates 58 locations across 19 countries. Associates engaged in the steel business are present at most of these locations, handling approximately 5 million tons of materials globally each year.

The Steel Division in Japan itself has just under 60 employees, with around 30% of them regularly seconded to domestic and international locations, working on the front lines of customer operations. Like many of our mid-level and younger associates, both Koto and I gained experience working at domestic and overseas locations during our 20s and 30s.

Rather than connecting with overseas customers through a computer screen or phone, everyone in the division has opportunities to experience the global nature of our business firsthand on-site.

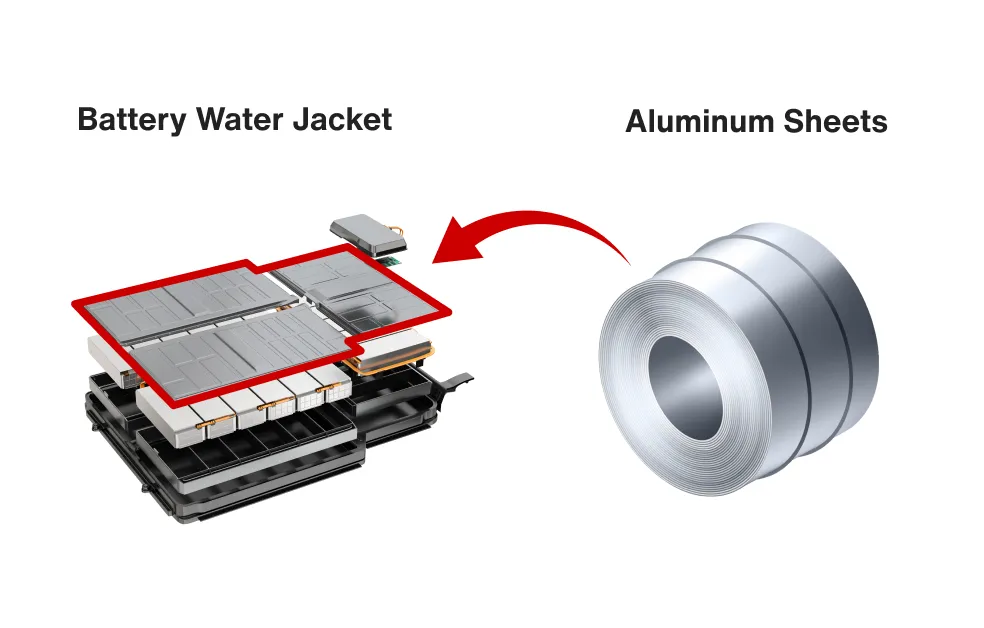

Koto: Our division handles a wide range of materials related to mobility, including steel sheets for vehicle bodies, as well as special steels and aluminum sheets used in engines and transmissions. Leveraging our global network, we deliver a variety of materials to production sites, meeting customer expectations.

In addition to simply moving materials from one place to another, we also provide value-added services by processing many of these materials to make them more user-friendly for our customers. For example, we operate two coil centers in China and one in India, where we process steel sheets to meet customer needs. In other locations, we have built mutually beneficial relationships with partner manufacturers to offer high-value-added services globally.

Responding to Electrification with Electrical Steel and Aluminum Sheets

- ーAs the electrification of vehicles progresses, lightweighting efforts such as replacing steel components with aluminum are also advancing. How is the Steel Division addressing these changes?

- Koto: In this so-called "once-in-a-century transformation," the amount of steel used in vehicles is decreasing, particularly around engines, due to electrification and lightweighting. However, on the other hand, the use of electrical steel in motor cores for electric vehicles is increasing. Capturing this replacement demand is one of our strategies.

While the overall amount of steel used in vehicles is declining, the demand for electrical steel is expected to grow significantly. Additionally, as electrification advances, the use of aluminum sheets to reduce vehicle weight is also expected to increase. We see this as a significant opportunity to expand our business.

You might wonder why the "Steel" Division is handling aluminum. The reason is that the customers who use aluminum sheets are often the same as those who use steel sheets.

- ーCould you elaborate on your strategies for electrical steel and aluminum sheets?

- Hozawa: Electrical steel is a material that is expected to face supply-demand imbalances in the near future, with demand potentially outstripping supply. To handle increasing volumes of electrical steel, it is crucial to design robust supply chains in advance.

Our specific approach involves becoming part of our customers' teams from the planning stages, helping to create optimal procurement framework. We work hand-in-hand with customers to develop systems and frameworks that enable stable supply.

By building strong relationships with customers and supply chain partners from the early stages, we ensure smooth procurement and supply operations when mass production begins.

As for aluminum sheets, we already have experience supplying them for automotive body applications. In fact, aluminum sheets we supplied are being used in commercially available vehicles. Building on this track record, we aim to expand into new areas where aluminum is increasingly being used due to electrification, such as battery cases and water jackets.

Comprehensive Support from Development to Mass Production, with a Focus on Global Expansion

- ーIt seems that the division's strength lies in its comprehensive support system from development to mass production. Could you elaborate?

- Hozawa: First, we gather detailed information on the materials used by automakers and search globally for materials that meet their requirements, including cost considerations.

Fortunately, through our long-standing global business activities, we have built strong relationships with material manufacturers in various regions, enabling us to propose materials that meet customer needs.

Additionally, we handle arrangements to verify whether the proposed materials are suitable for customer use. This includes coordinating on-site process verification and arranging trial materials to align with customers' development schedules.

To support stable mass production, we also propose supply chain frameworks. We take the lead in coordinating with supply chain partners to ensure a smooth and secure production launch. After mass production begins, we continue to support material supply and management to maintain the stability of our customers' production lines.

- ーWhat are your thoughts on the division's strengths in global expansion?

- Koto: One of our key strengths is that we are not tied to any specific steel manufacturer, allowing us to work with a wide range of material suppliers. Additionally, we have relationships with global steel manufacturers. We aim to leverage these strengths to further expand globally.

Regarding overseas operations, I personally spent about five and a half years stationed in Jakarta, Indonesia. Having a local presence is a significant strength of our division.

In Indonesia, we managed materials shipped from Japan and other regions, responding to customer needs through a supply chain built for stable supply. The local market includes numerous factories for four-wheel and two-wheel vehicles, transmissions, and parts manufacturers, making it a diverse and dynamic location.

Exploring New Value Creation through Open Innovation

- ーWhat are your future plans for developing new materials?

- Hozawa: In existing businesses, as alliances within the automotive industry progress, we see opportunities to propose competitive procurement framework for electrical steel, aluminum sheets, and even entirely new materials to customers beyond Honda. We aim to pursue these opportunities to contribute to enhancing our customers' corporate value.

In addition, we are working on building new business models that go beyond the scope of our existing operations. With the mobility industry facing an uncertain future, establishing new business domains is essential for Honda Trading's sustainable growth.

To this end, a company-wide organization has been established to focus on comprehensive new business development. Within the Steel Division, we have independently launched initiatives in 2024 to develop new businesses that create synergies with our existing operations.

One example is our open innovation efforts, where we aim to create new business models by combining our assets with the innovative technologies and services of startup companies. While our approach is currently proactive, we have already received proposals from several startups and are in the process of evaluating business models. Rather than leaving things to chance, we are committed to intensifying these activities to drive business expansion.

Recruitment

Recruitment Contact Us

Contact Us