Equipment,

Dies and Molds

We support the procurement of various equipment and peripheral equipment required for production plants.

Furthermore, we offer tailored procurement solutions that meet customer needs, encompassing all processes from overseas market research to equipment procurement, transportation, installation, and maintenance.

Products and Services

Through global procurement, we offer a wide range of equipment and dies and molds to meet customer needs. For press dies and testing jigs, we utilize our investee manufacturing companies in China and South Korea to provide integrated production, contributing to cost reduction for our customers.

To ensure quality, we conduct evaluation meetings with customers before shipment and handle all arrangements for import/export. For equipment delivery, we leverage the project management expertise and global network cultivated within the Honda Group to provide comprehensive support, including local preparation, technician acceptance, installation, and maintenance services.

Products and Services Offered

- Procurement and Supply of Various Production Equipment and Dies (available for both domestic and international markets)

- Export/Import Support, Compliance with Local Regulations, and Project Management - Equipment Installation and After-Sales Services

- Tools, Consumables, and More

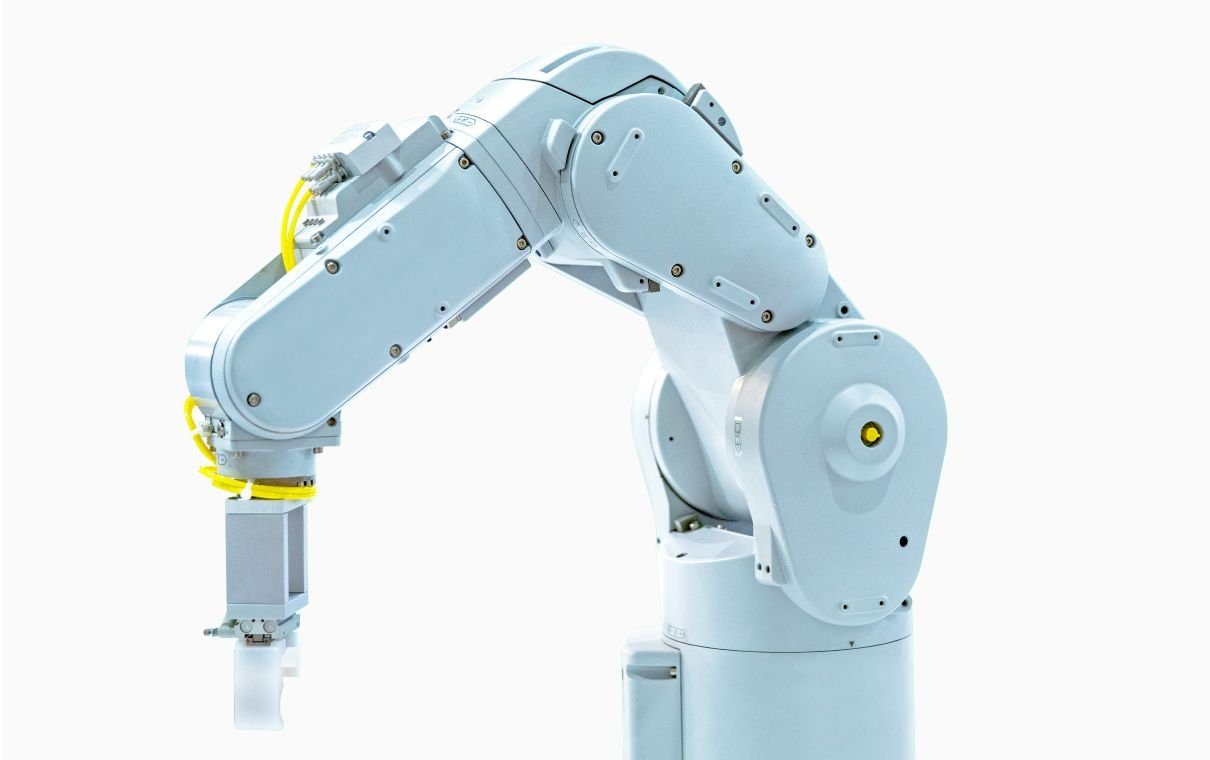

Equipment

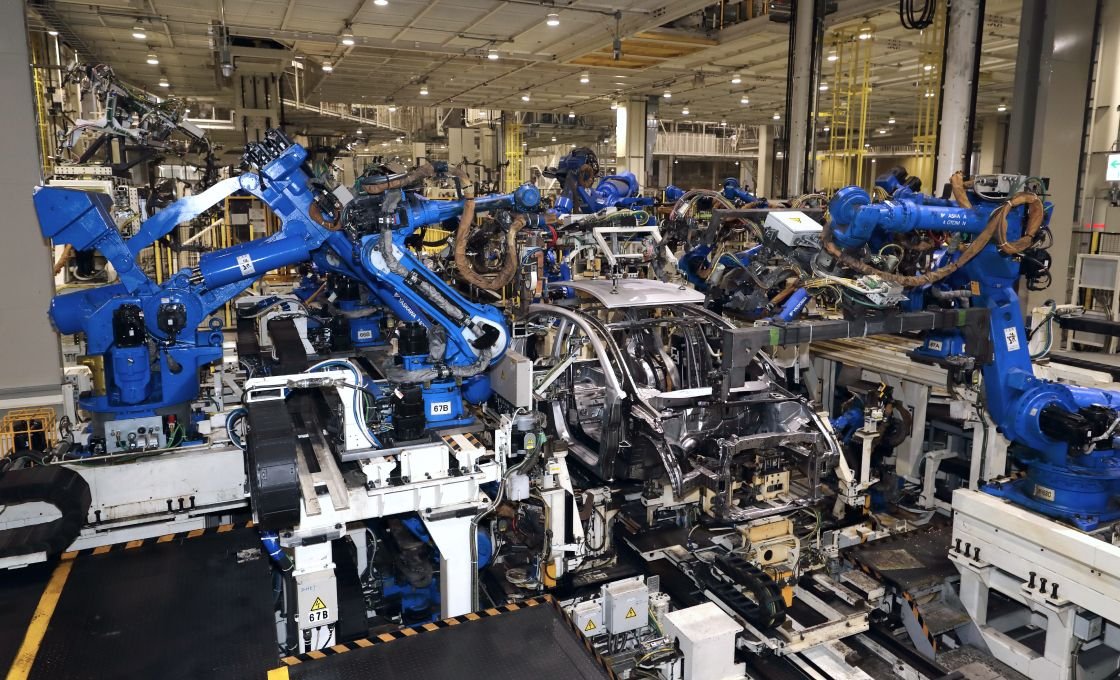

Car Body Domain

Equipment and peripheral devices required for automobile body manufacturing.

- Press: Press machines, hot stamping equipment, destack feeders, washing machines, etc.

- Welding: ABCD zone welding equipment, conveyor equipment, etc.

- Plastic Molding: Injection molders, conveyor equipment, etc.

- Painting: Painting line equipment, conveyor equipment, RB, etc.

- Assembly: Conveyor equipment, brake fluid injection equipment, etc.

- Vehicle Quality Inspection: Various testing equipment, etc.

Powertrain Domain

Machinery and peripheral equipment required for manufacturing automobile engines and transmissions, etc.

- Processing: N/C Processing machines, grinding machines, press-fitting/pressure testing machines, washing machines, inspection equipment, etc.

- Casting: HPDC, LPDC, GDC, melting furnaces, heating furnaces, holding furnaces, heat treatment equipment, sand molds, conveyor equipment, etc.

Other

Machinery, equipment, and peripherals required for production plants.

- Automation Equipment for Production Processes (e.g., visual inspection systems)

- Incinerators

- 3D Printers, etc.

Dies and Molds

Press Dies and Testing Jigs, Resin Molding Dies, Die-casting Molds, Mold Castings, etc.

Strengths and Features

Quick On-Site Response and Proposal-Based Sales

We provide end-to-end coordination, from manufacturer proposals and procurement to installation and after-sales services.

We also handle complex tasks requiring specialized knowledge, such as export control for security purposes and compliance with local regulations. Our global staff ensures trade compliance based on the laws of each country.

By gathering the latest technology and information on leading manufacturers from our global offices, we can propose equipment that meets customer needs. Our global network and extensive experience form the foundation of our swift and reliable responses to customer requests.

Comprehensive Die Manufacturing Services

We carefully select manufacturers based on detailed customer requirements and oversee the entire process, from die manufacturing and progress management to delivery and installation support at production sites. This comprehensive, one-stop service helps reduce costs. For press dies, castings, testing jigs, and die-casting molds, we work closely with our manufacturing subsidiaries and partner manufacturers to ensure thorough quality and progress management, from design to machining and finishing.

Solutions

Global Procurement of Equipment and Dies

We can procure equipment, dies and molds from multiple locations worldwide, leveraging our extensive network of offices.

For instance, we have successfully delivered dies produced in China to North America and transferred equipment manufactured in Thailand to South America. Additionally, we facilitate overseas procurement extending beyond Japan. Our extensive global network effectively addresses customer concerns regarding cost reduction and after-sales services.

Proposals for Equipment for Electric Vehicle Production Lines

In our projects to establish electric vehicle production lines, we offer insights on overseas manufacturers and assist in selecting equipment that aligns with production line requirements.

Even when partnering with new manufacturers possessing advanced technologies, we serve as intermediaries to facilitate smooth communication and manage projects. We ensure close collaboration with customers to drive the project forward effectively.

Recruitment

Recruitment Contact Us

Contact Us