Environment

As a member of the Honda Group and a socially responsible entity that prioritizes the preservation of the global environment, we are committed to providing solutions and engaging in corporate activities that contribute to the realization of a “society with zero environmental impact.”

The Concept for a “Zero Environmental Impact Society”

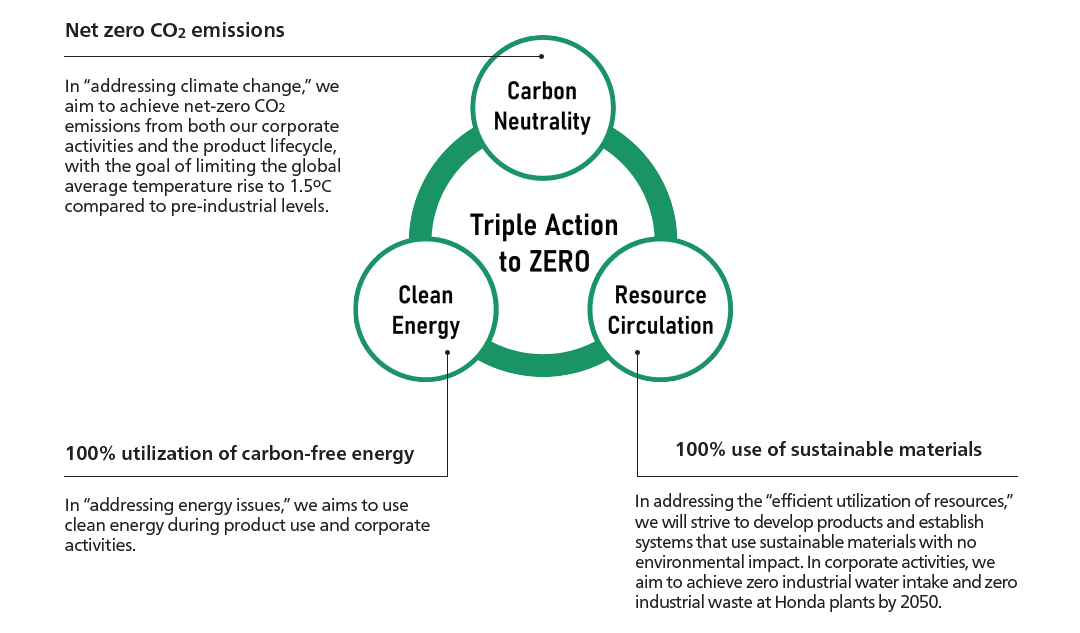

Triple Action to ZERO

Our efforts toward achieving a “society with zero environmental impact” are centered around the concept of “Triple Action to ZERO,” which integrates three key initiatives: “Carbon Neutrality,” “Clean Energy,” and “Resource Circulation.”

These three initiatives under “Triple Action to ZERO” are closely interconnected, and we aim to maximize their synergy by considering the chain of effects among them.

“Triple Action to ZERO” at Honda Trading

-

Carbon Neutrality

詳しくはこちらWorking Together with Customers Toward a Carbon-Free Supply Chain

-

Clean Energy

詳しくはこちらTowards a Carbon-Free Society, Bringing New Ideas to Energy Strategies

-

Resource Circulation

詳しくはこちらBuilding the Foundation for a Circular Economy to Achieve Truly Sustainable Mobility Manufacturing

Recruitment

Recruitment Contact Us

Contact Us