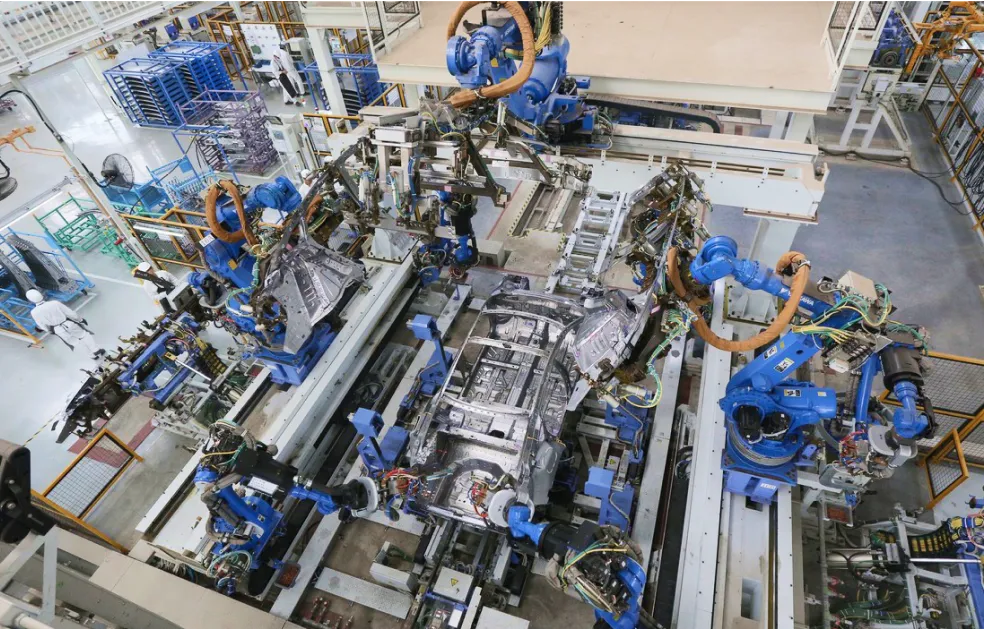

The Equipment & Environment Division handles a wide range of products essential for factory operations, including production equipment, dies and molds, tools, and consumables. In recent years, leveraging our accumulated experience and expertise, we have seen an increase in the use of our services by clients outside the Honda Group and in other industries. We spoke with two members of the Equipment & Environment Division about the current state of their efforts and their future outlook.

*Note: The information is current as of March 2025.

Offering Comprehensive Solutions Through Zero-Based Proposals and Consulting

- ーCould you tell us about the overview and key features of the Equipment & Environmental Division?

- Sakamoto: Our division handles a variety of products required for factory operations, including production equipment, dies and molds, tools, and consumables. Utilizing our domestic and international procurement networks, our role is to propose high-quality, optimal equipment to our customers.

In addition, we provide comprehensive solutions by addressing customer challenges, even developing new products from scratch when immediate procurement is not possible.

Okada: Adding to that, our core business extends beyond procurement to include project management and after-sales services. For example, we handle everything from aligning equipment specifications, managing overall schedules, and installing equipment to maintaining machinery and supplying replacement parts.

Sakamoto: Exactly. Much of our business is international, and within the Honda Group, we work with various stakeholders across the entire automotive production processーfrom upstream to downstream. This includes consulting on equipment specifications, budgets, transportation methods, and schedules.

- ーHow about your business dealings outside the Honda Group?

- Sakamoto: We also work with parts manufacturers affiliated with other automotive OEMs. By leveraging the on-site responsiveness and expertise we've cultivated within the Honda Group, and collaborating with our in-house manufacturing companies and partner companies, we've been able to secure ongoing orders from outside the Honda Group.

Okada: Since we invest overseas manufacturing companies for dies and molds, inspection tools, we can utilize this network to provide services to a broader range of global customers. Our strengths also include a global procurement network and expertise in compliance areas such as international taxation and export regulations.

Rapid On-Site Support and Customized Sales Powered by a Global Network

- ーCould you elaborate on how you leverage your global network in business development?

- Sakamoto: We have local subsidiaries and representative offices in 19 countries worldwide, constantly searching for new and competitive products for our customers on a global scale.

For example, we have owned dies and molds manufacturing company in China for many years, where we've accumulated experience, expertise, and technology together. Leveraging this strength, we've made proposals to various customers and built a track record of orders. Above all, our ability to respond quickly to issues in collaboration with local offices and our commitment to quality have earned us high praise, leading to continued orders.

Customers have expressed that by utilizing our services, they can entrust management to us with peace of mind and focus on their core manufacturing operations.

Okada: Beyond China, we're also actively expanding our network in neighboring countries. For instance, we've facilitated projects like introducing excellent equipment from Thailand into manufacturing sites in Vietnam. This kind of cross-border collaboration is possible because of the strong connections between our local subsidiaries and representatives in each country.

- ーHave you introduced overseas products to Japan?

- Sakamoto: Until May 2023, I was stationed in Brazil, where I discovered a unique local manufacturer producing equipment to save gas used in welding processes.

Using our network, I proposed expanding this product beyond Brazil to other countries, including Japan. The response was very positive, with comments like, "This is interesting," and "Great eye for innovation." We successfully exported the equipment to Japan, where it was adopted not only by automotive manufacturers but also by office furniture companies. The product continues to receive positive feedback in Southeast Asia and other regions.

Additionally, to meet customer needs such as cost reduction and environmental compliance, we've fully utilized our global network to introduce industrial measuring instruments from Europe and processing machines from Taiwan to Japanese customers.

Collaborating with Startups to Deliver AI-Based Visual Inspection Systems

- ーCould you share solutions that address changes in manufacturing, such as automation and personnel saving?

- Sakamoto: We began focusing on automation and personnel-saving initiatives in 2023, primarily proposing products for various processes in the press domain. Among these, we've seen a growing demand for automating visual inspections using AI.

For visual inspection automation, we've built networks with startups to explore and propose the most suitable technologies for our customers. Importantly, we don't just make proposals; we work closely with customers to verify how effectively these systems can be integrated into their processes. We place significant emphasis on customizing these services and systems.

In an era of labor shortages in manufacturing, utilizing AI to eliminate human variability and stabilize quality is an effective solution. However, since AI is still a relatively new technology in manufacturing, we are taking a step-by-step approach with our customers, leveraging our expertise in customization to ensure successful implementation.

- ーWhat are your key selling points for acquiring customers outside the Honda Group?

- Okada: Our strengths lie in project management, on-site responsiveness, and customized sales capabilities, all of which we've honed over the years.

As part of our "All Honda Trading" initiative, we've been actively focusing on external sales expansion. For example, our on-site responsiveness and customized sales capabilities, developed within the automotive industry, were highly evaluated by a major measurement and control equipment manufacturer, leading to an order for equipment installation in Southeast Asia.

Additionally, our experience and expertise in the automotive industry have sparked interest from other sectors. For instance, a major medical equipment manufacturer has approached us for consultations, recognizing the potential for new perspectives we can bring. Through these strengths, we're gradually gaining traction with customers in other industries, and we're starting to see tangible results.

As a "solution provider continuously chosen by customers," we are committed to bringing fresh perspectives to customer-centric problem-solving businesses. We encourage anyone with equipment-related challenges to feel free to consult with us.

Recruitment

Recruitment Contact Us

Contact Us