-

Carbon Neutrality詳しくはこちら

-

Clean Energy詳しくはこちら

-

Resource Circulation詳しくはこちら

Carbon Neutrality

Working Together with Customers Toward a Carbon-Free Supply Chain

We have identified “realizing a decarbonized society” as one of our Sustainability Material Issues.

In line with our action goals, we actively propose raw materials and recycled materials that contribute to CO₂ reduction, as well as promote environmentally friendly logistics. Through these efforts, Honda Trading is committed to proactively reducing CO₂ emissions.

Initiatives in the Manufacturing Domain

Our group’s aluminum manufacturing companies supply molten aluminum (liquid state) directly to customers’ nearby factories.

Additionally, we collect aluminum scrap, such as offcuts and defective products generated at customers’ production facilities, as valuable resources. These are then remelted and supplied back to customers’ factories as recycled aluminum materials.

Leveraging our capability to procure raw material scrap both domestically and internationally, we ensure a stable supply to our customers while contributing to CO₂ reduction through our corporate activities of recycling aluminum scrap.

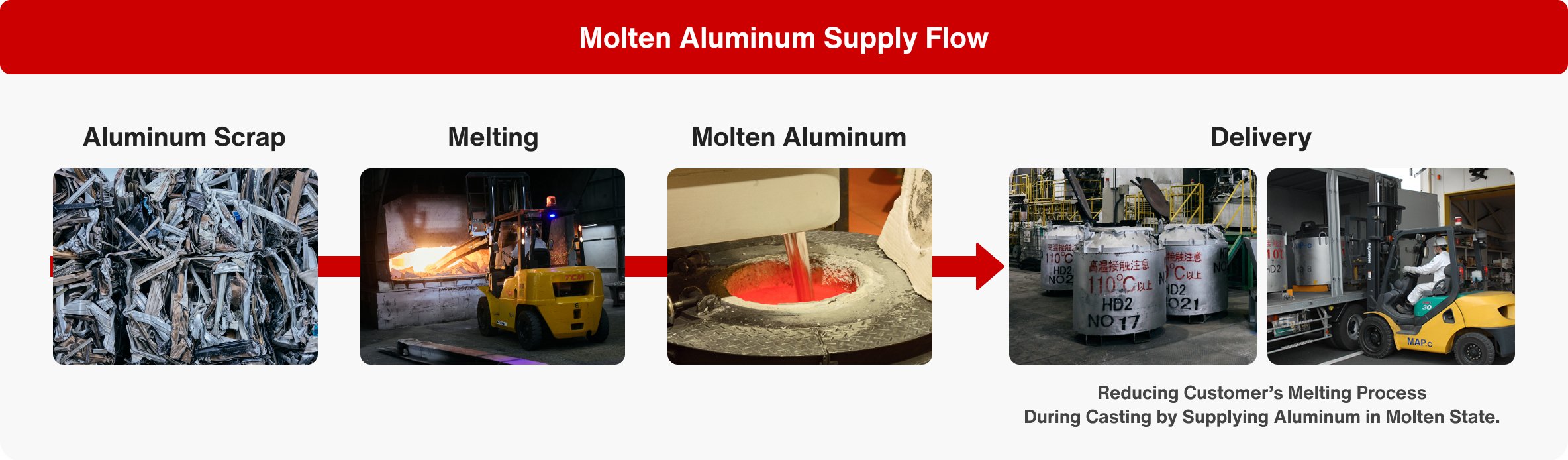

What is Molten Aluminum Supply?

In the conventional manufacturing process for aluminum cast parts, aluminum alloy manufacturers melt scrap to produce recycled aluminum ingots, which are then delivered to casting factories. At the casting factories, the delivered recycled aluminum ingots are remelted in on-site furnaces to manufacture aluminum cast parts.

With molten aluminum supply, aluminum is delivered in its molten state to casting factories, reducing the energy-intensive melting process from two times to one. This approach helps reduce the energy (oil, gas, electricity) required for melting and contributes to lowering CO₂ emissions in customers’ casting processes.

In 1994, we established the Honda Group’s first molten aluminum plant in Kumamoto, Japan. Since then, we have expanded operations to Gunma and Saitama in Japan, as well as to Indonesia and China.

Initiatives in the Transportation Domain

As a company that plays a key role in the global supply chain, we recognize the significant responsibility of reducing CO₂ emissions generated during cargo transportation.

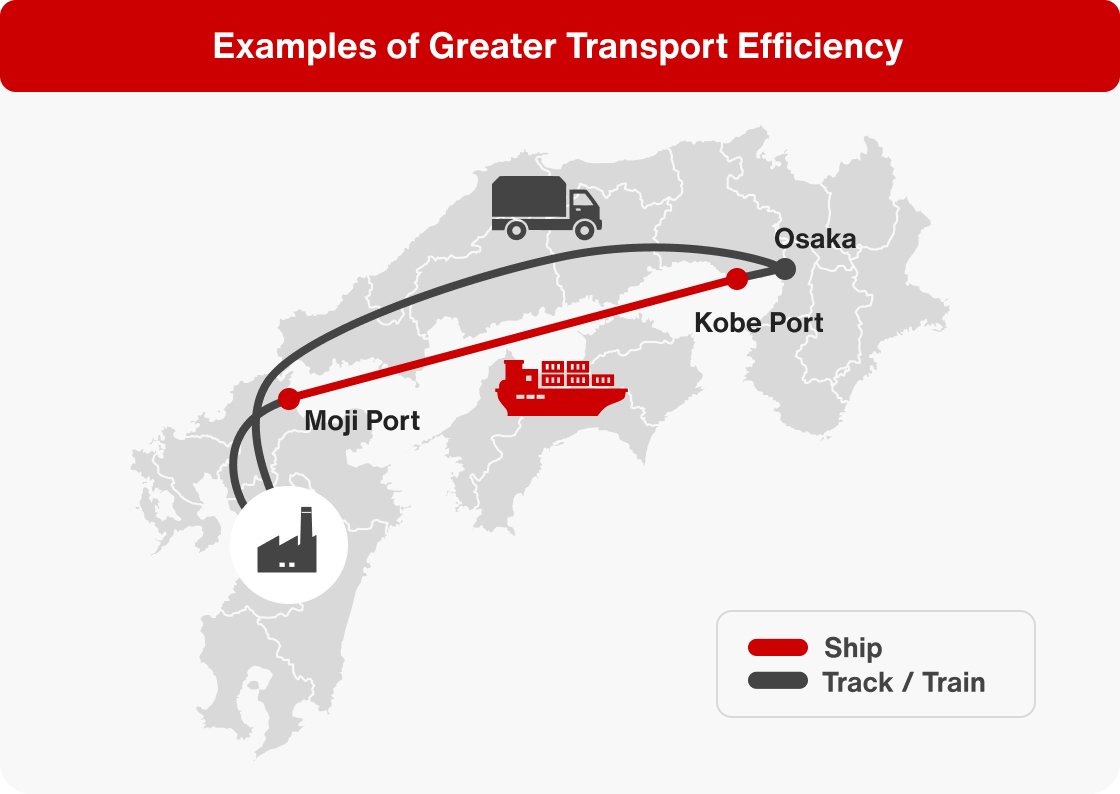

To improve transportation efficiency, we propose optimal logistics methods and transportation routes, such as consolidated logistics across departments and customers, and modal shifts*. Additionally, we actively introduce reusable returnable containers for packaging materials and work to reduce packaging materials where it does not affect the product.

Our proposals go beyond merely considering logistics costs for our customers, incorporating a comprehensive perspective that includes environmental impact.

*Modal Shift: Transitioning freight transportation from trucks and other vehicles to more environmentally friendly modes such as rail or ships.

For domestic transportation of cargo from Kumamoto to Osaka in Japan, we shifted from truck-only transportation to utilizing efficient ship transport between Moji Port and Kobe Port. This change reduced annual CO₂ emissions for this transportation route by approximately 30%.

-

Carbon Neutrality詳しくはこちら

-

Clean Energy詳しくはこちら

-

Resource Circulation詳しくはこちら

Recruitment

Recruitment Contact Us

Contact Us