2025.11.28

First Horizontal Aluminum Recycling Achieved in Japan’s Domestic Subway Cars

Tokyo Metro Co., Ltd.

Metro Sharyo Co., Ltd.

Honda Trading Corporation

Nippon Sougou Recycle Co., Ltd.

Nikkeikin Aluminium Core Technology Company, Ltd.

Suminoe Industries Co., Ltd.

—Recycling Discarded Railway Car Bodies into Interior Parts Reduces

CO₂ Emissions by Approximately 8 Tons—

Tokyo Metro Co., Ltd. (Head office: Taito-ku, Tokyo; President and CEO: Akihiro Kosaka; hereinafter “Tokyo Metro”), Metro Sharyo Co., Ltd. (Head office: Taito-ku, Tokyo; President and CEO: Hideki Nakazawa; hereinafter “Metro Sharyo”), Honda Trading Corporation (Head office: Chiyoda-ku, Tokyo; President and CEO, Representative Director: Tatsuya Natsume; hereinafter “Honda Trading”), Nippon Sougou Recycle Co., Ltd. (Head office: Takaoka City, Toyama Prefecture; President and CEO: Yasushi Takakura; hereinafter “Nippon Sougou Recycle”), Nikkeikin Aluminium Core Technology Company, Ltd. (Head office: Minato-ku, Tokyo; President and CEO: Hideo Iotake; hereinafter “Nikkeikin Aluminium Core Technology”), and Suminoe Industries Co., Ltd. (Head office: Kyoutanabe City, Kyoto Prefecture; President and CEO: Hirotomi Ono; hereinafter “Suminoe Industries”) have jointly achieved horizontal recycling of aluminum from Hanzomon Line Series 8000 cars to Series 18000 cars.*¹

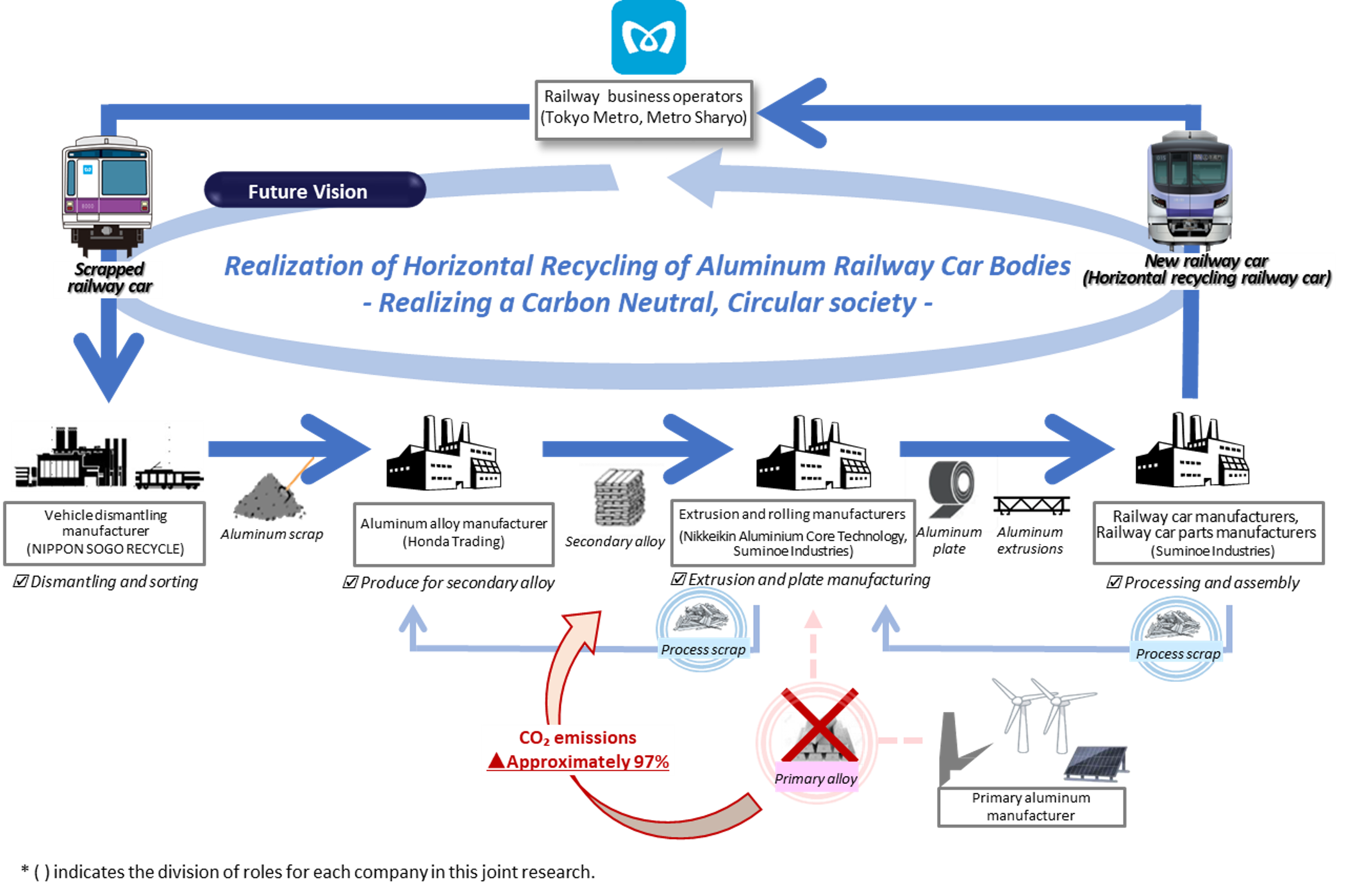

As part of a joint research initiative launched in FY2024 focused on horizontal recycling of aluminum railway car bodies, we successfully recycled a discarded Tokyo Metro Hanzomon Line Series 8000 car. The aluminum body was sorted by alloy type and repurposed—without any degradation in material quality—into interior components for newly manufactured Series 18000 cars operating on the same line. This achievement marks Japan’s first successful case of horizontal aluminum recycling in subway cars and has contributed to an estimated reduction of approximately 8 tons of CO₂ emissions.

Looking ahead, we aim to expand the scope of horizontal aluminum recycling in railway cars by leveraging the insights gained from this research. Our next focus will be on promoting collaborative efforts to enable the recycling of railway car body structures, which demand even stricter quality control standards.

Through this joint research, we are committed to advancing decarbonization and fostering a recycling-oriented approach within the railway industry. This includes reducing CO₂ emissions*² across the supply chain during the manufacturing of new railway cars, thereby contributing to the realization of a more sustainable society.

Form of recycling which involves recycling the waste into alloys of the same purity and composition, thereby maintaining the purity and alloy composition. Strict selection and adjustment are required to prevent deterioration.

*2 The effect of aluminum recycling

Aluminum requires a large amount of energy to produce primary aluminum from bauxite and generates a large amount of CO2. When recycled, aluminum requires only 3.4% of the energy and produces 2.8% of CO2 compared to the production of primary aluminum.

(Quoted from the “Inventory Analysis Report on Melting Scrap for Wrought Materials” by the Japan Aluminum Association LCA Research Committee, March 2023)

(Reference) News Release dated January 29, 2025

Memorandum of Understanding Concerning Basic Policies for Joint Research on Horizontal Recycling of Aluminum Railway Car Bodies Signed|Honda Trading Group

Details on the Achievement of Horizontal Aluminum Recycling from the Hanzomon Line 8000 series train to the Hanzomon Line 18000 series train

1. Background Research

Tokyo Metro currently owns one of the largest railway car fleets in the country, with over 2,700 railway cars, all of which have bodies made from aluminum alloys.

In general, aluminum requires a large amount of energy and generates a large amount of CO₂ during the production of primary aluminum, and when recycled, it is possible to significantly reduce CO₂ emissions by approximately 97% compared to the production of primary aluminum.*²

For this reason, Tokyo Metro, as a company that owns and operates a large number of railway cars, has been promoting the recycling of scrapped railway car bodies in order to take the lead in addressing global climate change and strongly promote the reduction of environmental impact.

However, horizontal recycling has faced technical challenges, particularly in the removal of steel, stainless steel, and resin components, as well as in the precise separation of aluminum alloy types. As a result, recycling efforts for discarded Tokyo Metro railway cars have so far been limited to cascade recycling into cast materials and similar applications, where component management is relatively straightforward. This has also restricted the use of recycled materials in new railway car bodies.

Through this joint research, we successfully established a precise method for dismantling and sorting discarded railway car bodies by aluminum alloy type. This breakthrough enabled horizontal recycling of aluminum into interior parts of newly manufactured railway cars—including extruded aluminum sections, which had previously been difficult to recycle due to their complex shapes and material specifications.

2. Overview of the Initiative

(1) Dismantling and Sorting of Discarded Railway Cars

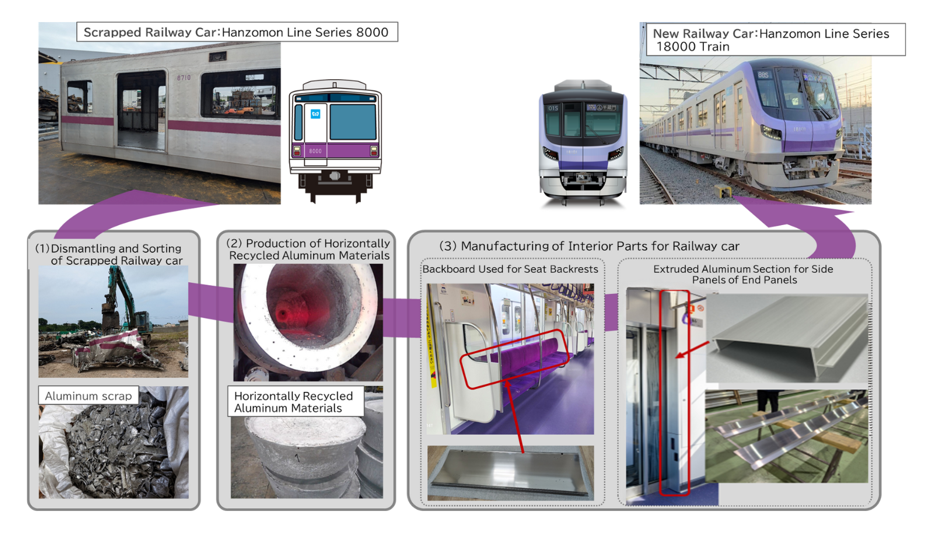

The body of a discarded Tokyo Metro Hanzomon Line Series 8000 train car was carefully dismantled, with iron, stainless steel, resin, and other non-aluminum materials thoroughly removed. The remaining aluminum scrap was then roughly sorted by alloy type, based on the original function of each section of the car body. Only aluminum alloys suitable for horizontal recycling—specifically Series 5000 and Series 6000—were selected and separated for reuse.

(2) Production of Horizontally Recycled Materials

The selected aluminum scrap was melted (with impurities removed and detailed composition verified) and used to produce horizontally recycled materials:

➀ Sheet material (Series 5000)

➁ Extrusion billets, which were then used to manufacture extruded aluminum sections (Series 6000).

The quality of the recycled materials was verified to be on par with those produced from virgin aluminum ingots.

(3) Manufacturing of Interior Parts for Railway Cars

Horizontally recycled materials were used to manufacture interior parts for new railway cars:

➀ Backboards (Series 5000) for seat backrests

➁ Extruded side panels (Series 6000) for end panels

These components were applied to the interior of the newly manufactured Hanzomon Line Series 18000 train (Set No. 18119).

3. Outcomes of This Initiative

During the dismantling and sorting process of discarded railway cars, we confirmed that aluminum scrap could be selectively sorted by alloy type—specifically Series 5000 and Series 6000—making it suitable for horizontal recycling.

We verified the quality of the Horizontal recycling aluminum materials and successfully produced aluminum sheets and extruded sections that meet the standards for use in subway car interior parts. Furthermore, by using horizontally recycled aluminum, we achieved a reduction of approximately 8 tons of CO₂ emissions in the production of interior parts.

4. Future Outlook

To broaden the future application of horizontal aluminum recycling in new railway cars, our goal is to establish a circular use of aluminum within car body structures—components that demand even higher standards of quality control due to their structural role. Building on the insights gained from this research, we will continue to advance collaborative studies aimed at further reducing CO₂ emissions throughout the supply chain during the manufacturing process of new railway vehicles.

5. Other Information

A PR sticker will be displayed inside the Hanzomon Line Series 18000 train that uses horizontally recycled aluminum materials.

The design illustrates the aluminum horizontal recycling process:

Going forward, Tokyo Metro plans to display similar stickers in other trains that incorporate horizontally recycled aluminum materials.

Recruitment

Recruitment Contact Us

Contact Us